Since 1954 Micromold has machined, fabricated and molded plastics for Original Equipment Manufacturers (OEMs) of valves, pumps, instruments, and many other kinds of products and equipment.

We are owned and run by engineers dedicated to meeting each customer’s expectations.

We are proud to:

-

Provide collaborative, responsive customer service

-

Satisfy your quality needs

-

Help solve your technical and engineering problems.

We make thousands of different parts in runs from one to a million

-

In a well-equipped manufacturing facility

-

Working with engineering plastics, especially fluoropolymers, and molding PTFE

-

Often to provide high corrosion resistance and high purity.

Our skills are enhanced as we help our customers’ engineers

-

Develop new and upgraded products and systems

-

Resolve technical issues in the use of plastic parts

-

Optimize parts for greater value.

The result is a broad range of OEMs

-

Many of whom we have served for decades

-

Who engineer products for a diverse group of industries including: bio-pharm, chemicals, electric utilities, food and dairy, medical equipment, mining, nuclear power, petrochemical, pharmaceuticals, plating, pollution control, polymers, pulp and paper, refining, semi-conductors, specialty chemicals, transportation, wastewater treatment, water purification and many others.

We serve equipment manufacturers in a broad cross-section of the process industries. These include manufacturers of:

-

Biotech, Pharmaceutical, and Medical Equipment

-

Electronic and Communications Equipment

-

Environmental Monitoring Equipment

-

Flow Measurement Systems

-

Food Processing Equipment

-

Liquid Level Measurement Systems

-

Process Piping

-

Process Vessels

-

Pumps

-

Semiconductor Tools and Equipment

-

Valves

-

Water Treatment and Purification Equipment

-

And Many Others

Fabrication

We maintain a full complement of plastic fabrication equipment. Our capabilities include the fusing, fillet, and butt-welding of all weldable plastics. A pioneer in the fusing and welding of PTFE, Micromold has special capabilities with this and other difficult-to-weld fluoroplastics. We have programmable ovens for stress-relieving and annealing plastic materials and parts, which are essential both for precision machining and for stress-reduction in weldments. Our precision machining, finishing, and polishing equipment can achieve the fine finishes needed for sealing or bearing surfaces of many industrial parts.

Customer Support

Our focus has always been on providing knowledgeable, efficient, and responsive customer service—which is why our customers consider us one of the easiest companies in our industry to do business with. We stock parts to satisfy each customer’s just-in-time and lean-manufacturing system needs. For non-stock items, we continually monitor progress, and we always consult with our customers regarding potential schedule changes. Our order processing, inventory control, and shop scheduling are managed using a modern ERP to fulfill customer requirements quickly and accurately.

Our Proud History Serving OEMs

Founded in 1954, Micromold set out to engineer and manufacture seals and gaskets for clean-in-place (CIP) applications in the dairy and beverage industries. Our scope quickly broadened to include other fluid-handling components. We were pioneers in the processing and application of Teflon® PTFE and Dyneon™ TFM™. In addition to fluoroplastics, Micromold has, from the beginning, machined and fabricated a full range of engineering plastics with a focus on the manufacture of sanitary and corrosion-resistant plastic parts for the process industries.

OEM

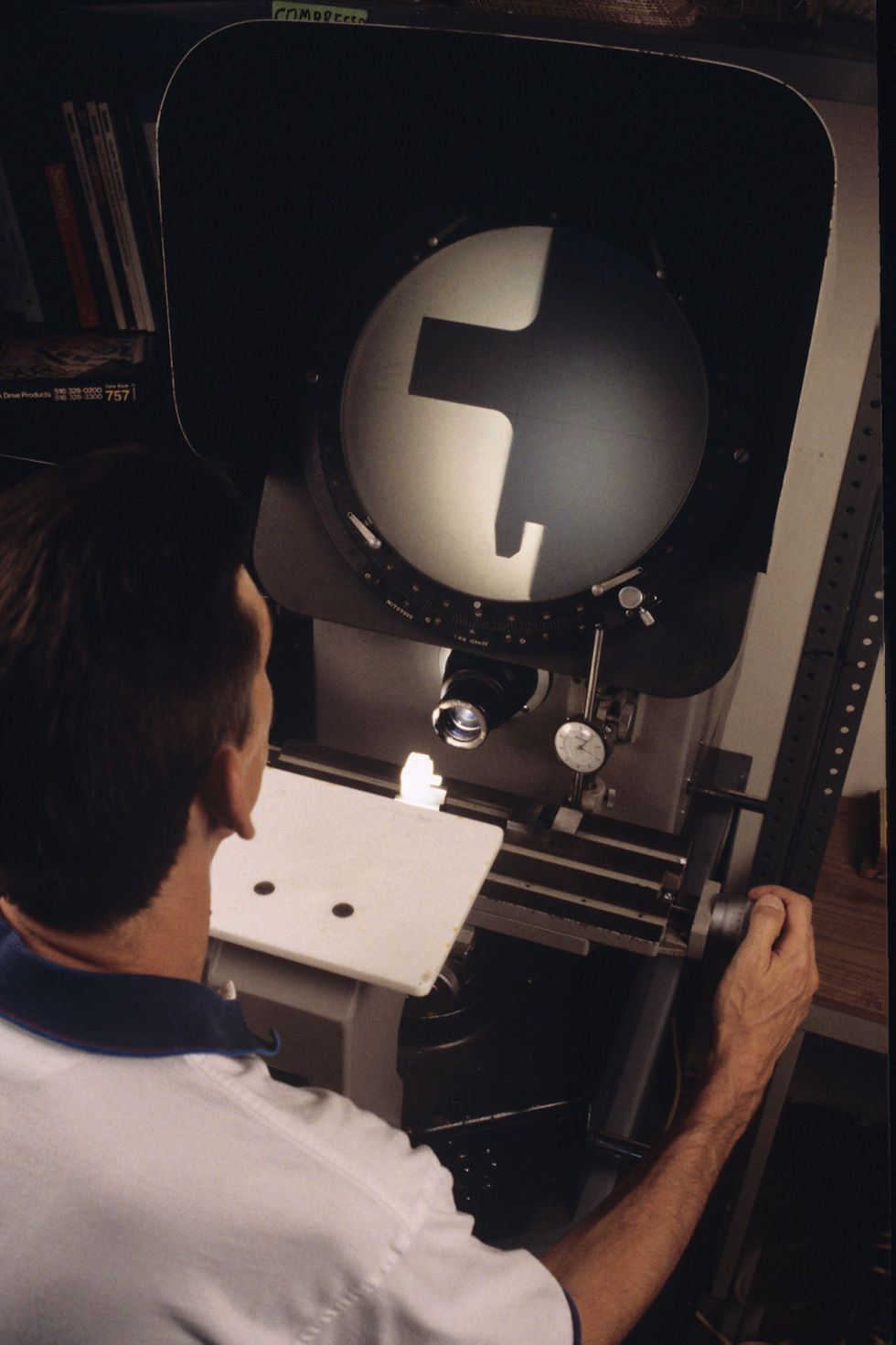

Machining

We machine and fabricate nearly all the engineering plastics. Our complete precision machine shop includes CNC turning and vertical machining centers, automatic screw machines, and manual toolroom and production machines. Our facility is climate controlled throughout, which is critical to enabling precision tolerances in plastics machining. We also make metal parts needed to complement our plastic products.

Molding

We compression-mold virgin and filled PTFE resins to form billets that feed our machining and fabrication operations.

Quality Systems

Maintaining high quality is our constant resolve. We believe strongly in Deming’s philosophy: to build in—not just inspect for—quality in our manufacturing. To achieve this, we use our number-one asset: the knowledge and skills of well trained and experienced employees. Of course, we make appropriate inspections and maintain material traceability throughout manufacturing. We will be pleased to share our quality manual with you, and we will make our quality records available for your review.

Cross-functional teams analyze quality issues that may arise, to identify root causes, and to institute corrective and preventative actions as needed. These discussions, together with customer feedback, are part of our continuous improvement philosophy which, over the years, has yielded for our customers numerous enhancements in Micromold's manufacturing processes, quality control, and administrative procedures.

Engineering and Technical Support

Since our beginning, Micromold's engineering foundation has engendered a problem-solving orientation that continues to this day using modern CAD/CAM tools and capabilities. We are eager to assist our customers with their technical questions, such as evaluating material trade-offs, helping to develop economical designs and working out unusual design problems.

About Our Line of FLUOR-O-FLO® Fluid Handling Products

In addition to our machining and fabrication services, we manufacture proprietary fluid-handling products under the trade name FLUOR-O-FLO® that are sold through distributors to process industry plants and OEMs. These include PTFE Pipe and Fittings, PTFE Valves, PTFE and PVDF (Kynar®) Y- and Basket-Strainers and others that can be found here.

Micromold™, Microflon™, FLUOR-O-FLO®: TM–Micromold Products; Kynar®: TM–Arkema, Inc.; Kel-F®: TM–Daikin America, Inc.; Vespel®, Delrin®, Teflon®: TM–Chemours™ (formerly DuPont™); Ryton®: TM–Chevron Phillips Chemical Company LLC; Celezole®: TM–Hoechst Celanese Corporation; Dyneon™, TFM™: TM–3M

Typical Parts

Typical of the many different types of components we manufacture for OEMs are:

-

Ball and Butterfly Valve Seats

-

Bearings

-

Bellows

-

Bushings

-

Centrifuge Bowl Gaskets

-

Envelope Gaskets

-

Floats

-

Insulators

-

Lantern Rings

-

O-Rings

-

Sanitary Gaskets

-

Seals

-

Socket-Weld and Threaded Fittings

-

Stem Seals

-

Washers

Engineering Plastics

The plastics we machine and fabricate most frequently include:

-

Virgin PTFE

-

Microflon™ Low-Creep PTFE

-

Filled PTFEs

-

PFA

-

PVDF (Kynar®)

-

PCTFE (Kel-F®)

-

Polypropylene

-

PEEK

-

Polymide (Vespel®)

-

PPS (Ryton®)

-

PBI (Celazole®)

-

UHMW-PE

-

HDPE

-

LDPE

-

Nylon

-

Acetal (Delrin®)

-

Acrylic